OVERVIEW

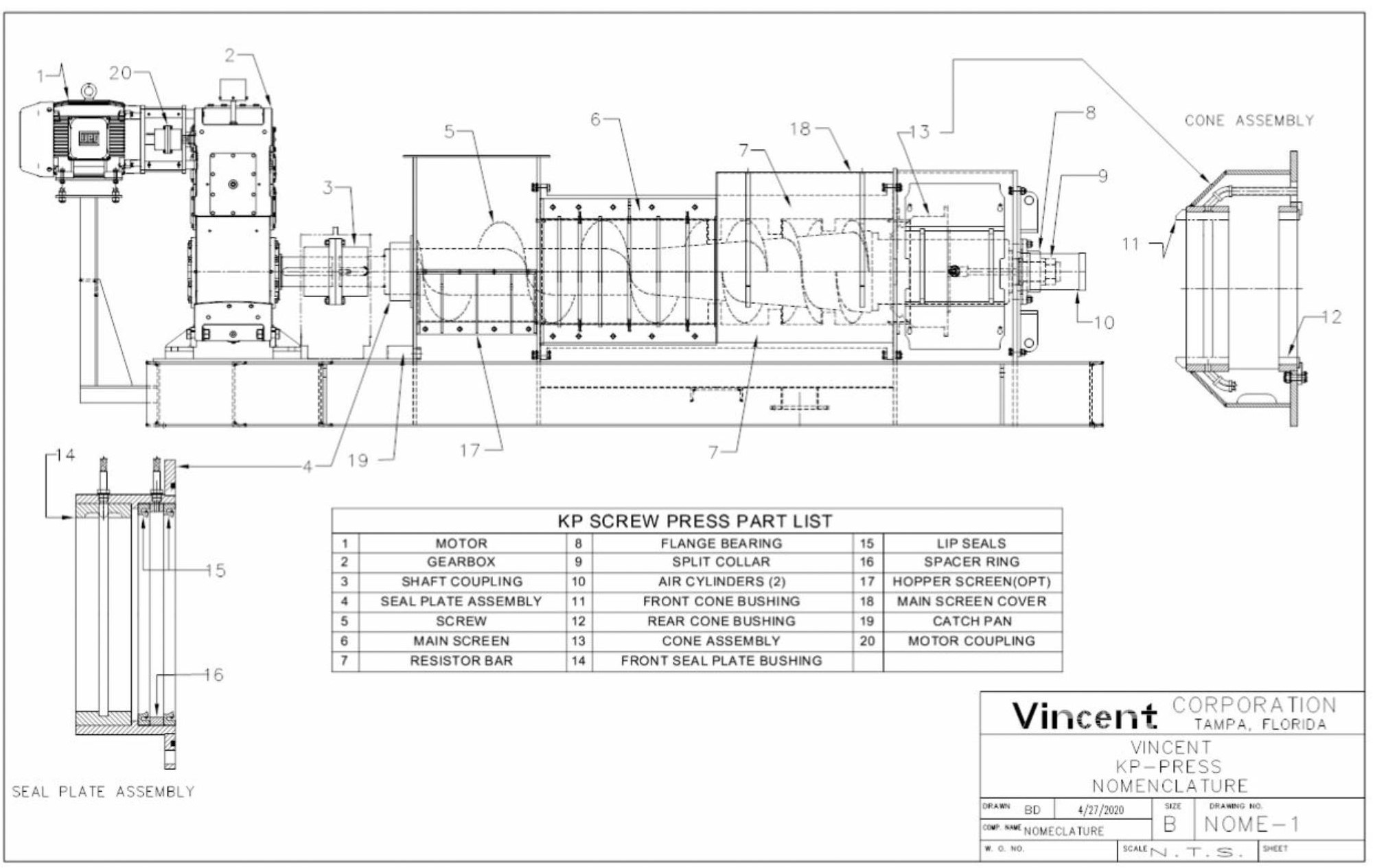

The Vincent KP Press consists of a screw rotating within a screen housing, a flanged inlet hopper, and a discharge opening. At the discharge end, the mouth of the screen housing is closed by a pneumatically actuated cone which moves back and forth on the screw shaft in proportion to the internal pressure in the screen frame. This motion is opposed by the cone cylinder thrust, thereby regulating the discharge of solids. An air regulator is provided to adjust the pressure on the cone. The liquids, which are squeezed from the wet product, escape through the screen housing and are caught in a built-in pan under the screen.

The screw is driven by a fixed speed electric motor that is C-face mounted to a gearbox. The gearbox reduces the RPM from the typical 1750 RPM output of the motor to an appropriate speed for the application, 5 – 50 RPM. The hollow bore gearbox mounts directly on the screw shaft and is flange mounted to the machine.

The numbers in the model designation stand for the nominal diameter of the screw in inches.

As the press has been adapted to many different applications, options have been added to the press. These include interrupted or continuous flighted screws, conical screws where the shaft increases in diameter, different shape inlet hoppers, different style cones, etc. As a result, not all the information contained in this manual will apply to your press.

SAFETY

A screw press, like any screw conveyor, is totally unforgiving. If clothing or a limb gets caught in a rotating screw, the screw will not stop.

• Wear safety glasses around the press.

• Avoid loose-fitting jewelry or clothing, including high-visibility safety vests. If vests are required, the Velcro, tear-away type are recommended.

• Always lock out electric and compressed air before working on the press.

• Dewatering presses squirt liquid out, particularly if screen covers are removed. If material is hot, acidic, or caustic, do not remove screen covers while operating.

• Wear gloves when performing maintenance.

• When removing the tailstock and discharge mechanism, watch for pinch points and hinged assemblies. Be careful when removing or installing the screw and screen when they are fed through the C-plate as this is a particular pinch point.

• Never stand near a press being suspended during installation.

• Provide an E-stop button near the press.

• Keep hands out of the press inlet and press cake discharge area.

RIGGING

Be sure to properly support the press when lifting it from the truck. Usually a sling positioned under the inlet hopper, on the side closest to the gearbox, finds the center of gravity. On bigger presses, do not lift just one corner of the press, as it is possible for the frame to deflect, shifting the screw within the press.

INSTALLATION

These presses are typically called horizontal screw presses. This doesn’t mean that the presses must be installed exactly level from inlet to discharge. Presses are often installed at an upward angle. Consult the factory if you need to install the press at an angle above 15° as an adjustment to the gearbox may be required.

Be careful not to rack the press when tightening the mounting bolts. In the case of large presses, do not just bolt or weld the press down to a level foundation! Instead, first place the press where it is to be installed. Next, place shims between the press frame and the steelwork (or floor, concrete pedestal or foundation) to fill any gap where the press is to be anchored. Only after shimming (or grouting) should the press be pulled down tight. Doing otherwise can rack the frame of the press, and this can cause screw-to-screen interference.

A large press must be mounted solidly, preferably to a foundation or structural steel. If a press draws its full rated horsepower without the press being anchored to the floor, the frame of the press can twist.

For maintenance, the screw is removed through the cake discharge end of the press. Allow the space required.

To suit individual conditions, a hollow bore gearbox can be rotated 180o, 90o either way. Consult the gearbox manual or Vincent factory in these situations as it is likely that the oil level in the gearbox will have to be adjusted.

Material can be fed into the press many ways. You may need to allow for return feed of overflow material if more is fed to the press than it can take. When material is piped to a press in a closed piping system, it is important to have a 2″ vent line open to the atmosphere, along with an overflow return line. The vent is necessary to prevent a siphon effect which can induce a vacuum in the inlet hopper and reduce press capacity. The return line should empty above the surface of the return pit. The overflow should fill less than half of the cross section of the return line.

Spill containment is a consideration which should be considered, because it may be possible for un-pressed material to purge from the cake discharge of a press.

We recommend that a manual disconnect, for killing power to the motor, be installed close to the press.

A variable frequency drive (VFD) programmed for either variable speed or auto-reversing may be required, depending on the application. If not, the use of a reversing starter switch is recommended; they cost only a little extra. Such a switch is handy for clearing a jammed press.

It is possible that, when operating intermittently with very wet material left in the press between runs, the liquid may loosen the cake plug at the discharge. This might cause the plug to blow out upon start-up. To minimize this condition, the press can be installed with the discharge tilted upwards.

PRESS COMPONENTS

A/B/C/D-PLATES

There are four vertical plates making up the frame of the press, called out in the Nomenclature drawing at the end of this manual. The motor is connected to the gearbox with a stub shaft protruding toward the press. The stub shaft is connected to the screw with a coupling. Going into the inlet hopper is the inlet hopper seal assembly attached to the A-plate. This A-plate forms one wall of the inlet hopper.

The next plate is the B-plate. It forms the downstream wall of the inlet hopper. The screen starts at the B-plate. There may be a notch (or pair of notches), called a Cord Cutter, in the B-plate. Also, there may be a bar called Brian’s Stripper welded to the B-plate, inside the inlet hopper; it is designed to kiss the edge of the screw flight as it passes. These two features prevent long fiber pieces from balling up at the exit of the inlet hopper. See the “Cord Cutter and Stripper Pins” section ahead.

The next plate, the C-plate, supports the discharge end of the screen. The discharge cone touches the C-plate when the cone is in the closed position.

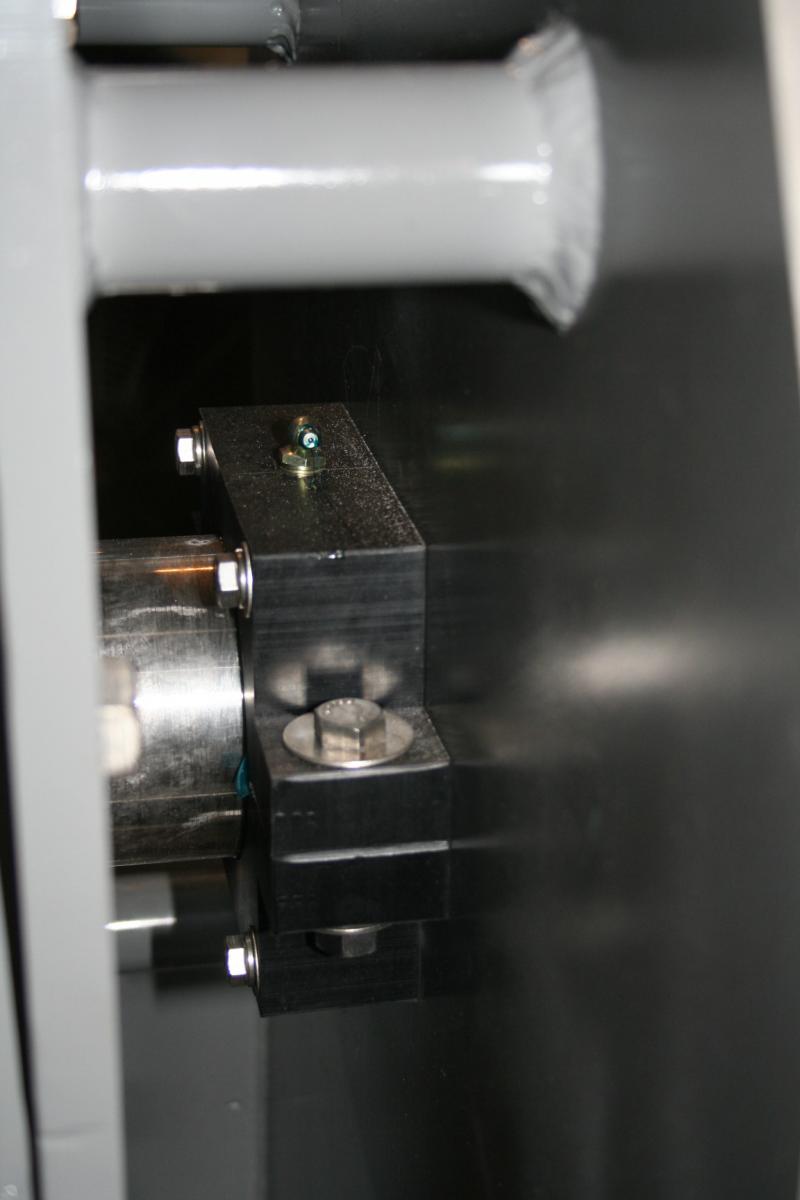

The final plate, the D-plate, has the twin air cylinders mounted on it. The screw shaft terminates at the D-plate via the attached flange bearing.

AIR REGULATOR

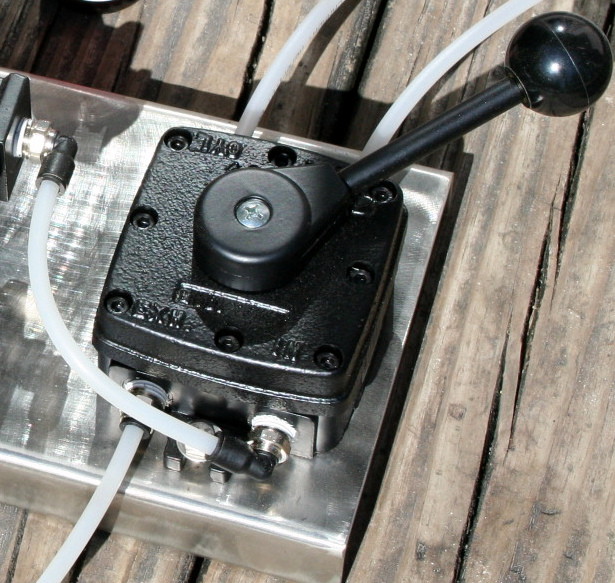

To regulate the air pressure of the discharge air cylinder, presses are supplied with an air pressure regulator along with a Parker 4-way cone positioning valve. These are typically installed near the cone end of the press. [Until recently FRL (Filter, Regulator, Lubricator) sets were provided to regulate air pressure. Most air cylinder manufacturers now recommend against the use of lubricators.]

The Parker valve allows manual selection of the shut, open, or “neutral” position. This valve connects air supply from the regulator to one end of the air cylinder, while simultaneously opening the other end to atmosphere. The vent line on the 4-way valve allows air to escape when pressure is switched from one end of the air cylinder to the other.

Continuous air flow from the Parker vent line indicates a leak inside the air cylinder, or possibly a faulty 4-way valve.

The neutral position of the Parker valve is used only in testing. If left in the neutral position, the cone will not move unless it is pushed open by press cake. If, later, the flow of press cake is diminished, the cone will remain in the position to which it was pushed, and purging can occur.

DISCHARGE CONE

The principal adjustment of the press is made with the discharge cone. The cone is the component at the cake discharge end of the press that acts as a door or stopper plug to restrict material from leaving the press. The more pressure exerted by the discharge cone, the drier the cake material will be leaving the press. Also, the motor amps can be expected to increase with added pressure, and throughput may decrease.

The discharge cone is moved in (actuated) either by an air cylinder or, rarely, by weights. Typical air cylinder pressures are in the range of 30 to 60 psi. Some materials will press only in a low range, say 10 to 20 psi. Other materials may press best with a pressure of 60 to 100 psi. Air consumption is minimal in all models, 1 to 2 cfm.

During initial, first-time start up, presses with air cylinder actuators are generally started up with the discharge cone in the withdrawn position. This will avoid an unnecessary jam. With the air cylinder models, the discharge cone mechanism can readily be positioned in the “open” (withdrawn or “out”) position.

Note that with many materials it is necessary to start the press with the discharge cone in the closed position at low air pressure. Thin or soupy materials, like pumped manure or clarifier underflow, can tend to purge right through the press if the press is operated with the discharge cone open [in the withdrawn (“out”) position]. However, with materials that are dry to begin with, such as sawdust or plastic wash tank sludge, it becomes more important to start with the discharge cone in the open position. This is because these materials may tend to jam or overload the press. Similarly, high freeness materials, from which the water falls away freely, will tend to jam in a press. Start the press with the cone open, then close it with low air pressure initially, when running such materials for the first time.

Most presses are operated 24/7. Once you are through the initial startup, it will be unlikely that your press should have the cone opened before starting. Most operators rarely open or shut the cone once it is set. However, with the KP-24 and KP-30, it is recommended to cycle the cone in and out once per shift. This ensures that grease for the bushings is spread across the screw shaft.

As the pressure on the discharge cone is increased, not only will the cake become drier, but the flow through the press may also be reduced. With very slippery or slimy feed material it may be possible to apply enough discharge cone pressure to stop the flow altogether.

High discharge cone pressures can result in increased quantities of suspended solids in the press liquor.

Care must be taken if a press is to be left running at a very low pressure like 10 psi. If some fiber enters between the cone bushing and the screw shaft, it will take more than that much pressure to close a cone which has been pushed open by a heavy flow of cake. The result will be either high moisture content in the cake or, worse, purging.

With some feed materials, the press can be operated with the discharge cone in the withdrawn position. The screw alone may do enough compressing and dewatering to produce a cake at the discharge.

It is acceptable to open the discharge cone, in most cases, during normal operating conditions. This allows inspection, while in operation, of the discharge end of the screw and screen. This will give the operator a chance to observe operation with minimum dewatering and maximum throughput. It is also a good technique for purging bad material, i.e. either jammed or spoiled material, from the press. (Do not try this trick if you are pressing hot or chemically aggressive materials.)

Where very low air pressure is required for proper operation, it may be practical to put the cone positioning valve in a neutral position, halfway between open and closed. A press cannot be left permanently in this condition: keep in mind that a slug of cake will push the cone open, and it will not re-close on its own afterwards.

An unusual technique is to set the air pressure so that the cone normally stays completely shut. A timer is used to periodically open the cone. The closed period is determined by the amount of time required for press cake to accumulate in the press. This type of operation is used with slippery or slimy press cake that cannot be dewatered to sufficient firmness to force the cone open. The duration of the “cone open” period is long enough to dump much of the press cake that has been formed. Vincent Cone Timer panels are available at a minimal cost.

Once through start-up, the cone is almost always left in the closed position at whatever air pressure has been found to be effective. A plug of cake will be left around the cone whenever the press is turned off; this will normally clear on its own accord on restarting the press. To prevent a potential jam upon restarting, it is a good idea to open the cone for a few minutes prior to shutting down the press, after flow to the press has been stopped. Although there will be solids left in the press, they won’t be highly compacted.

There are a few applications where the air cylinder is removed and replaced with a jacking bolt. This is used if the cone pushes completely closed even with the lowest air pressure. It results in operating the press with a fixed discharge annulus, or air cylinders with linear actuators are available.

CONE BUSHING(S)

The cone rides on the shaft of the screw. “Cone Sleeve” is the name given to the portion of the screw on which the cone rides. There are dual bronze or UHMW bushings in the cone to support and guide it, and to protect the Cone Sleeve journal surface of the screw shaft. Sometimes the bushings are lubricated with liquid from the material being pressed, such as the juice from apples or water from pectin peel. Sometimes there is a grease fitting provided for lubricating the bushings or to minimize leakage of press liquor through the cone bushings. And sometimes, an AutoLube is included for automated lubrication of the cone bushing.

Bushing lubrication is extremely important when materials that are dry (like paper mill screen rejects) are being pressed. By the time such materials reach the discharge of the press, they do not have enough free moisture left in them to adequately lubricate the cone bushings. In these applications the operator should, at the start of each shift, pump grease in until it comes out between the cone bushing and the screw shaft. Then he should open and shut the cone three times in order to spread the grease.

Rarely, presses are supplied with additional lubrication fittings so that water, in addition to grease, can be metered to the bushings as a lubricant.

Automatic grease systems are available but only usable for fixed (non-rotating) cones. These should be the high pressure (900 psi) electric or battery variety. Vincent provides these for critical applications, especially pulp & paper.

Liquid leaking past the cone bushings drains out the back of the cone (at the air cylinder end of the press). Almost always it is minimal compared to the flow of press cake. However, a pan can be provided to collect this liquid and drain it into the main flow of press liquor.

SCREW / SCREW CONFIGURATIONS

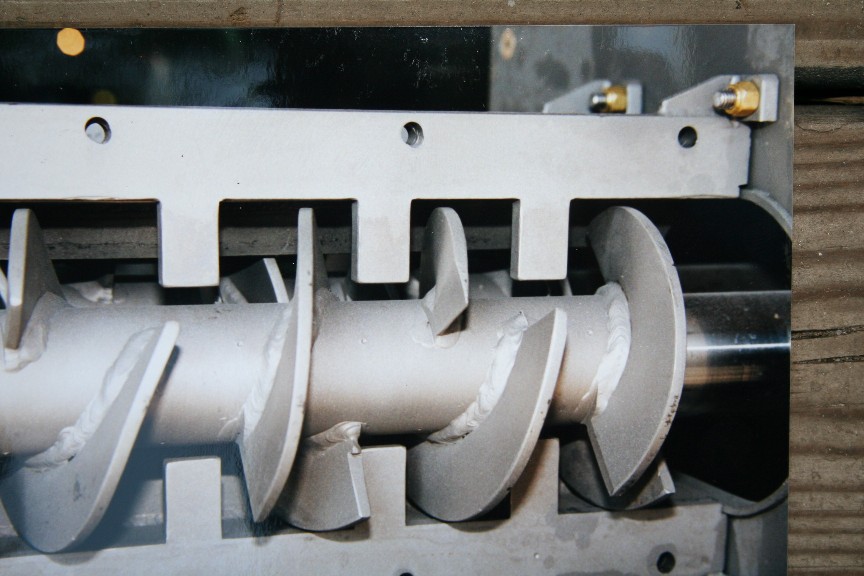

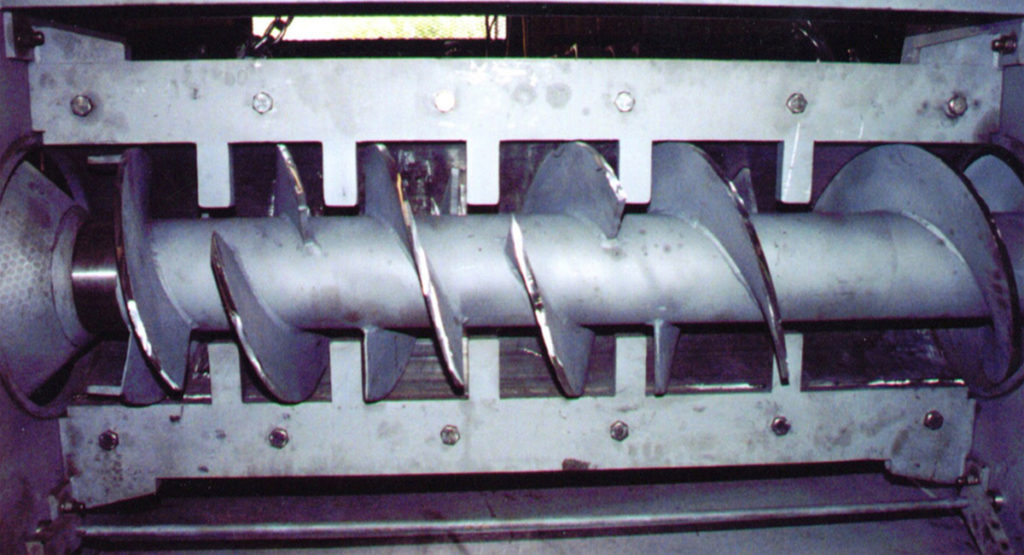

Most Vincent screw presses use the Interrupted Flight Screw design. The interruptions leave room for stationary resistor teeth that are mounted outside of the screen. These teeth go through the screen and reach almost to the shaft of the screw. This design of screw press stands in contrast to a Continuous Screw design. The main advantage of the interrupted design is that solids material must accumulate in the interruptions until sufficient consistency is reached for the solids to be pushed toward the cake discharge. There is a reduced tendency for the material being pressed to co-rotate with the screw. Also, there is more agitation within the press and, consequently, quicker and more thorough dewatering. Pushing the material through the compression zones past the teeth will also shred the material a bit.

Interrupted Flight Screw with Resistor Bars

Interrupted Flight Screw with Resistor Bars

For applications where tramp material is more likely to enter the press, a continuous-flighted screw is often used. Typically, if maximizing dryness is a priority, the screw shaft is tapered to provide increased compression.

Screw with Tapered (Conical) Shaft

Screw with Tapered (Conical) Shaft

All screws start with a feeder section of continuous flights. This picks up material in the inlet hopper and pushes it into the screen section. The feeder section ends at the first resistor tooth. This feeder section of the screw is followed by compression stages where the flights have reduced pitch. The reduction in pitch of the flights results in compression of the material going through the press.

A screw configuration referred to as Sterile Butterfly is occasionally used. Sterile is a reference to a company, not cleanliness. There are a reduced number of flights on this screw, and the flights do not wrap as far around the shaft as is normal. This screw design is good for high throughput of materials which are easily dewatered and might jam the press.

WING FEEDERS

Sometimes there are blades welded to the outside tips of the last two flights of the screw. Called “Wing Feeders”, these are mounted parallel to the discharge screen surface. Care must be taken that wing feeders are not made so long that they hit the face of the cone when the cone is in the closed position.

Wing feeders can serve two purposes: (1) In the case of materials that want to channel out the discharge of the press, like pineapple and spent brewer’s grains, long wing feeders break

up the channeling flow and (2) For abrasive applications, short knobby wing feeders are provided as sacrificial wear elements.

When certain materials are fed through a screw press, clumps of dry material may accumulate between the wing feeders and the screen. This buildup can cause wear of the screen. Should the problem occur, grind off the wing feeders.

NOTCHES

Sometimes it is necessary, during press operation, to have the screw wipe the screens clear of blinding material. This is best achieved by having notches in the outer edge of the screw. Fibrous material accumulates in the notches and brushes away slimy material which may be blinding the screens. Shallow notches (1/16″ wide by 1/16″ deep, 1-1/2″ apart) in the outer edge of the screw flights work well. Notching is easy to do while in the field, using a grinder with cutting wheel or a portable band saw. Typically, notching is done from the B plate to the second resistor tooth. Many Vincent presses are supplied with notches.

RESISTOR TEETH

The interrupted screw design press has stationary teeth that protrude into the flow of material as it passes through the press. These fit into the gaps of the screw where there is no flighting. They stop just short of the shaft of the screw. These resistor bars are on top and bottom of the screens and the screens bolt up to them.

Rarely, the resistor teeth are shortened, usually by half, to increase the capacity of the press. Removing the teeth altogether will result in co-rotation and jamming.

Occasionally, the resistor teeth are drilled so that fluid can be injected into the press during operation.

SCREENS

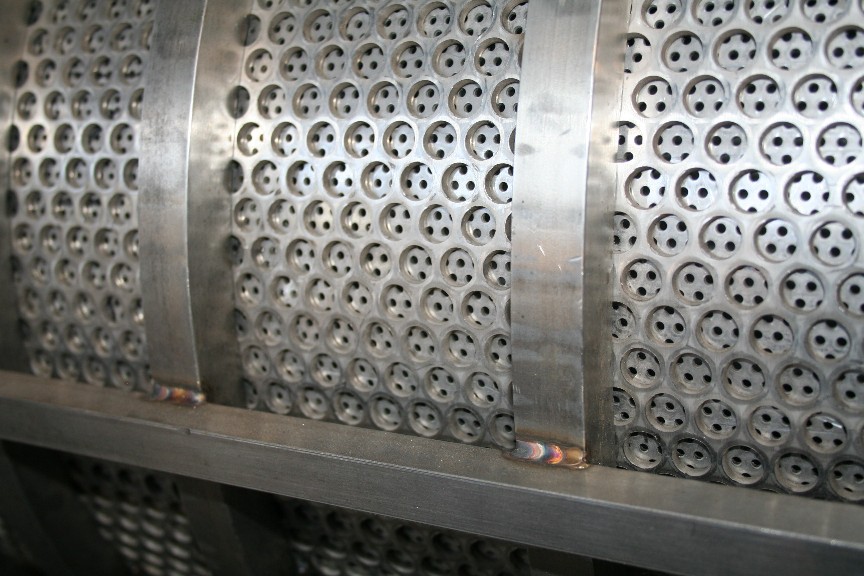

The screens of the press are made either of wedgewire or profile bar (slotted screen) or perforated stainless sheet (round holes).

Screens made of wedgewire come standard with 0.015″ to 0.020″ slot width; they are also available with slots that are 0.006″ to 0.060″ wide. With slot widths less than 0.012″ there is a tendency for the screen to blind (be covered over) with the material being pressed. However, they work well in alcohol and oil separation. Changing the slot width generally has little impact on the clarity of the press liquor or the dewatering capacity of the press. These screens are reversible as most wear will occur at the discharge end. This doubles the life of the screen. When worn, the entire wedgewire assembly must be replaced.

Perforated metal screens are usually a simple sleeve made from rolled perforated plate which is held in the screen assembly. These are less durable but usually only the inner screen, the screen insert, must be replaced, reducing cost.

The most common damage to a wedgewire screen is for part of the surface to be smeared over from being rubbed by the screw. This rarely is bad enough to affect press performance. Profile bar screens generally work satisfactorily with 30% or even more of their surface smeared over. Smeared screens can be remedied by running a box cutter blade through the slots. Small holes can just be patched with sheet metal to extend life. In cases of severe wear or damage, it is common to patch a screen. Stainless sheet metal is used for this. The reduction in drainage surface is of little consequence as the screens have ample open area.

Standard perforated screens have a hole size of 0.094″ diameter, although material with 0.050″, 0.033″, down to 0.023″ holes can be supplied. Surprisingly, usually there is little difference in the degree of filtration achieved by either changing hole size or going to a slotted profile bar screen.

Frequently, increased press capacity can be achieved by changing a perforated screen to one with smaller holes. This unexpected result arises from a combination of factors: (1) smaller hole screens are made of thinner sheet metal, so the press liquor has a shorter distance to travel before it falls free from the screen, reducing the chance of blinding and (2) particles which fall into and plug a larger hole will roll over a smaller hole. Minor rubbing between the screw and screen is normal, although, obviously, hard rubbing will cause wear and premature failure of the screen. With a clearance greater than 3/16″, the dewatering performance of the press can start to deteriorate; this depends a lot on the nature of the material being dewatered.

The most common cause of screen failure ties to failure of the outboard support bushing. If the bushing holding the end of the screw wears out, it can let the screw move enough to rub against the screen.

Profile Bar (Wedgewire) Screens

Profile Bar (Wedgewire) Screens

Perforated Screens

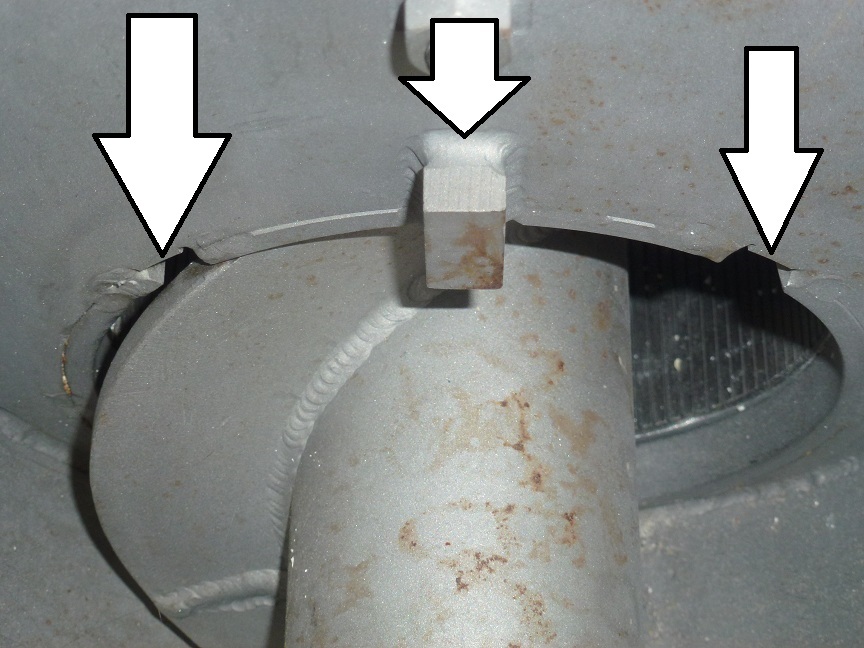

CORD CUTTER AND STRIPPER PINS

Sometimes long stringy material will be pinched where the feeder portion of the screw goes through the hole in the B-plate. This material will co-rotate with the screw and build into a bundle which reduces flow through the press.

A groove, like a 3/8″ deep keyway, is cut halfway through the hole in the B-plate. We call this a Cord Cutter. Material trapped between the flight and the hole in the B-plate will pop up slightly as it passes the Cord Cutter. The result is that the material is sheared loose.

A part called Brian’s Stripper may be welded to the B-plate, inside the inlet hopper. It goes in a position so that the flight lightly kisses the stripper as it goes past. This strips the material away. Strippers are made of square bar.

MOTOR / GEARBOX

Vincent presses are almost always supplied complete with a motor. Standard motors are 60Hz, Inverter Duty, TEFC, 230/460V. We will supply whatever motor is called for where the press is headed, 575V, 50Hz, whatever. Motors used are standard, off the shelf motors, easily replaced if needed from your local motor distributor.

Specialty motors are available upon request, including stainless, washdown duty, explosion-proof, etc.

Standard gearboxes supplied are NORD parallel shaft. Gearboxes are supplied with the oil at the right level for horizontal mounting. If the press is mounted off horizontal, a change could be required in oil level. Sometimes, to increase capacity, the press is sped up to 120 Hz or a 3600 RPM motor is installed. If your press is going to be run at high speeds, NORD recommends changing the oil to synthetic.

Both a motor manual and a gearbox manual are supplied toward the end of this manual.

A-PLATE SHAFT SEAL

Consult the Parts List contained in this manual to determine what type of seal plate assembly you have. The Seal Plate is bolted to the A-plate. This housing may be solid UHMW (ultra-high molecular weight polypropylene or polyethylene) and it may contain one or two Johns Manville (JM Clipper) lip shaft seals. There may be a grease fitting on this plate; the grease is used to reduce leakage and to help prevent fibrous material from entering and damaging the screw shaft.

Generally, seals are allowed to drip once they start leaking. They are replaced only in conjunction with major maintenance, as when the screw is removed from the press.

In some cases, we have found that leakage from a shaft seal can be stopped by simply selectively loosening or tightening the four bolts holding the seal housing to the A-plate.

Seal Plate (L) and Split Seal Plate (R)

VARIABLE FREQUENCY DRIVES (VFDs)

In this era of dropping costs, Vincent recommends the use of an inverter VFD to start, protect, and operate the screw press. With a VFD it is possible to establish the optimal combination of screw speed and discharge cone air pressure. The VFD also can be used to reverse the press in case of a jam or to slow it down or speed it up during upset conditions.

VFDs can be programmed to automatically stop and reverse the screw at set intervals. This is a good feature when the material tends to blind the screen. Reversing the screw will wipe the screen clear and liquid draining will return to normal. The auto-reverse function is also useful for applications where long stringy material wraps itself around the screw. The reversing action will knock free (untie) the stringy material.

Vincent is also more frequently using level controls, particularly in those applications where the flow to the press can vary substantially. The level controls can be tied to the VFD or a control system to speed up the press when it reaches a certain level or to gradually increase screw speed or decrease backpressure to increase press throughput.

VINCENT CONE TIMERS (VCTs)

For some applications a timer is used to periodically open the cone. There are two timer settings on the cone timer. Timer 1 determines the interval between cone openings. Timer 2 determines how long the cone remains open. Both are set by trial and error, manually opening and closing the cone using the cone positioning valve and then setting the timers accordingly to make it automatic.

Cone timers are most frequently used when there is no level sensor. With abrasive materials, low flow to a press maintained under compression will prematurely wear the screw and screen at the discharge. As an example, we had a location where flow to the press would stop for hours and the wood waste material would get completely dry, creating a “Presto Log”. When the flow started again, the presto log would not move, blowing out the screens and bending back screw flights.

Alternatively, the cone timer is used with slippery or slimy press cake that cannot be dewatered to sufficient firmness to force the cone open.

Cone Timer panels are available from Vincent for a minimal cost.

RUNNING THE PRESS

START UP

Check the inlet hopper first. Sometimes debris (or this owner’s manual) ends up in the inlet hopper. Before putting power to the screw press, it is advisable to bump the motor or even rotate the screw by hand. This will prevent damage to the press in case tramp material has been left in the press. Also, the screw may have shifted so as to hit the screen. (Minor rubbing is normal; it will go away once there is material in the press.) To turn the screw by hand, remove the fan guard on the motor and turn the fan blades. The screw of the press turns in a counterclockwise direction, when viewed from the drive end of the press.

Check to make sure that compressed air is being supplied to the regulator and that the cone can be opened and closed. Set the backpressure at a low level and/or start with the cone open.

1. Start the press. Minor screw-to-screen rubbing is normal and will go away when material is fed to the press.

2. Begin feeding material to the press. It’s helpful to have someone watching the level in the inlet hopper to ensure that the press isn’t overloaded.

3. When material starts appearing at the discharge end, close the cone if it’s open. Increase backpressure on the cone until the moisture level in the press cake appears to be as dry as you’d like. Continue monitoring the level in the inlet hopper as increasing backpressure will influence throughput. You may need to increase screw speed in tandem with increasing backpressure to get desired dryness and adequate throughput. See the next section on screw speed.

SCREW SPEED (RPM)

In general, the slower the screw speed, the greater the dewatering. Longer residence time in the screened area results from lower screw speed, which allows time for more thorough dewatering. Unfortunately, it also means reduced throughput capacity.

A small change in screw speed, like 15%, will generally not result in a measurable change in performance of the press. This is particularly true for the interrupted flight screws. Continuous flighted screws show more reaction to changes in screw speed. In any case, it’s not going to be a linear relationship. That is, doubling the screw speed will not double the throughput. And you do reach a point of diminishing returns.

FEEDING / PRE-THICKENERS

Material can be fed into the press many ways. Commonly, screw conveyors, pumps, transition chutes, pre-thickener screens or cyclone separators are used. Consider making provision for return of overflow material if more is fed to the press than it can take. Spill containment should be considered.

Also, material can be dropped from a shredder or cyclone separator into the press. A shredder is used to increase capacity and dewatering in the case of low bulk density materials like lettuce leaves, alfalfa, onion peel, and corn husk, or to prevent blockage.

Level in the Inlet Hopper: Most commonly, the best screw press performance is achieved if the material in the inlet hopper stays just at the top edge of the screw. Usually presses work best with only atmospheric pressure in the inlet hopper. In order to minimize static head, press headboxes are kept short, and level controls are used to minimize the depth.

When a pump is used to feed a press, the system can be either open or closed. We recommend the open system where little or no pressure exists in the inlet hopper, thus preventing the press from being force-fed. In this arrangement either there is an open return line allowing flow back to the source feeding the press, or level is controlled in the inlet hopper. It is best to have a line that allows material to re-circulate past the press inlet. This will prevent pressurizing the inlet of the press, which can cause both blinding of the screen and purging from the cake discharge.

A port on the side of the inlet hopper is frequently provided on larger Vincent presses. It is used to view the level of material over the screw. It has a bolted cover because it is rarely used.

If a fluid is piped through a sealed cover which is bolted to the inlet hopper, force-feeding is possible. A by-pass tee should be provided so that the pressure in the inlet hopper is minimized. In addition, a 2″ vent line, open to the atmosphere, must be provided to prevent siphoning material in the inlet hopper out through the recirculation line.

Inlet hopper pressure over one to four psi can force fibrous material against the screen to blind off the screen, resulting in unsatisfactory performance.

At pressures above 10 to 15 psi in the inlet hopper, it is possible to blow the “plug” of press cake that forms at the discharge of the press. Un-screened liquid will purge from the cake discharge. Exercise caution if either hot or hazardous material is being pumped into a press.

At inlet hopper pressures of 40 psi and above, the shaft seals will be blown out of their housing. At pressures around 60 psi the screen will start to separate from its support plates, resulting in bypassing of feed material directly into the press liquor flow.

Pre-Thickening: Sometimes either a static (sidehill or parabolic) or rotary drum screen (RDS) must be mounted over the inlet hopper to pre-thicken the flow ahead of the press; the tailings (solids) from the screen can be funneled into the press. This arrangement is desirable when the feed to the press is dilute. We’re often asked what the optimal feed consistency is. It’s different in just about every application, but with fibrous material, we’ve had success with consistency as low as 1% solids. Generally, thicker is better, but that’s not an iron cast rule.

BUILDING A PLUG

For the press to work, a plug of cake must form between the cake discharge spout and the pressure cone. The press will almost always do this on its own accord as material is fed into the press.

In the case of sloppy materials like manure and DAF sludge, it may be advisable to start off by first packing the discharge of the press with any available fibrous material.

Alternatively, the press can be turned on and the feed pump allowed to run just long enough to fill the feed line and the press. Then shut off the pump, leaving the press running, and wait until no more liquid drains from the screen of the press. Repeat this process until a plug of cake starts to open the cone.

ADDITIONAL HINTS

VACUUM EFFECT

In some applications, typically slimy materials, increased screw press capacity can be obtained if the area outside of the screen is under a vacuum. This can be achieved by mounting the press at a high elevation, with the press liquor drain line dropping below the surface of a drain tank or pit.

That is, the drain line from the press should go below the surface of the pit or pond into which it drains. If this line is relatively small in diameter and has a steady downward slope, a vacuum will be induced around the screen of the screw press. The mass and velocity of press liquor flowing through the drain line create this vacuum. To draw air bubbles downwards with the press liquor, the velocity of the fluid must be greater than five feet per second.

The cover over the screen of the press will have to be sealed, usually with Silicone.

The amount of vacuum is a function of the elevation between the press and the drain pond. For good results, the press should be mounted on a stand that is 20′ tall or higher.

INSTRUMENTS

The most useful instrument to have when testing a press is an ammeter. The load drawn by the drive motor of the press is indicative of how much work the press is doing. The higher the amps, the better the dewatering. Also, the higher the amps, the closer the press is to jamming, and the greater is the abrasive wear. Very low amps indicate little dewatering is being done; the screen is blinded, low compression is taking place, or the flow into the press has stopped.

In the case of pressing liquids that contain dissolved sugars or salts, a refractometer is valuable for assessing press performance. The Brix of the inbound flow, the press cake, and the press liquor will all be the same figure. The higher the Brix, the higher will be the solids content of the press cake and press liquor.

If dissolved (soluble) solids are present, the suspended (insoluble) solids (fiber) in the press liquor are generally measured by filtering and washing a sample and drying the filter paper in an oven. Dissolved solids will be washed from the sample during the washing process.

STOPPING THE PRESS

In the case of intermittent or batch operation, it is recommended that the control panel for the feed pump or conveyor which feeds the press should have a timer. This timer should be set to have the press run for two minutes after the feed pump (or conveyor) shuts off. Opening the cone during this two-minute period is helpful. This will partially clear the press so that it will not trip out on overload when it is re-started. (This applies in high torque applications or in installations where the material in the press dries out or freezes.) An extreme case occurs when pressing spent coffee grounds and some paper mill fibers. Each time the press is turned off, the cone must first be opened for two minutes. If this precaution is not taken, nasty damage to the press screw or screen can occur when the press is re-started.

Minimize the time that the screw press is run with no material being fed into it. The last material admitted to the press will dry to powder, and it can cause severe accelerated abrasive wear.

DOUBLE PRESSING

Some processes benefit from what is called double pressing. This means that the cake coming from the press is run through the press a second time (or through a second press). If little moisture is removed in the second (double) pressing, then it is known that the liquid removed in the first pressing is all the free liquid that there is to be pressed out.

Sometimes water is added to the cake in between the first pressing and second pressing. This is done to enhance the recovery of dissolved sugars in the original press cake. Molasses can be added to press cake between the first and second pressing. This is used to infuse dissolved sugar into the cake, increasing the solids content of the final press cake.

Capital-effective double pressing can be achieved by using an inexpensive Soft Squeeze Series KP screw press for the first pressing, following with a tighter-pressing Series CP/VP in the second position.

MOISTURE CONTENT

Most industries are concerned with what the moisture level is in the solids coming from the press. Paper mills and corn wet milling typically talk in terms of percent solids in the press cake. Either way, it’s a measure of the same thing, just from a different angle. When thinking of how dry something is, keep in mind that pine bark is 55% solids (45% water).

A screw press separates free water. This will leave organic water in the press cake. The organic water is either bound to, or part of, the animal or vegetable molecules. Mechanical pressure alone will not remove organic water; it takes heat or chemistry. Frictional heat from the press can remove organic water, but this obviously should be avoided. For chemistry, see the “Hydrated Lime, Gypsum and Alum” section. For heat, see the “Fluid Injection” section.

To determine the moisture content of a material (feed to the press, press cake, or press liquor), a sample should be weighed and dried overnight at a temperature slightly less than 100o C. (If sugars are present, use less than 70º C to prevent caramelizing.) The sample should weigh six or more times the tare weight of the sample tray or cup.

The moisture content of press cake varies considerably. Tomato press cake will be 90% moisture. Orange peel will be 80%, unless it is reacted with hydrated lime, in which case it will go down to 72% moisture; add molasses and it will go to 65%. Dairy and hog manure will come out at 70% moisture, unless there is sand or sawdust in the sample, which will reduce the moisture content. Cellulose fiber from a paper mill (knots, screen rejects, primary clarifier underflow) will come out about 50%. However, if secondary (biological) sludge is added, then the moisture content of the cake will go up considerably. With high ash content in paper mill samples, moisture may go down to 40%. Moisture contents of only 25% or less can be achieved pressing things like sand, eggshell, glass, and plastic chips.

The heat from steam injection can change the chemistry of the material being pressed so that cake with lower moisture content is produced. This blanching or parboiling effect works with fish and orange peel, for example.

COMPRESSION

A screw press achieves compression using several methods: (1) The discharge cone of the press causes backpressure on the material being dewatered. The higher the cone pressure, the greater the liquid removal. (2) The pitch of the flights of the screw tightens as the material is conveyed through the press. This forces liquid to go through the screen. (3) The diameter of the shaft of the screw may be increased progressively, forcing material outward, against the screen. This is a conical shaft design. (4) Forcing material past resistor teeth as it moves toward discharge.

Force-feeding (supercharging) the press and applying a vacuum to the outside of the screen are two additional methods which may achieve compression. These two are used infrequently because the performance improvement is rarely justified by the expense.

MEASURING THROUGHPUT

The best way to measure throughput capacity of a press is to collect timed samples of press cake and of press liquor. This should be done during a period of sustained, stable operation, rather than by timing a batch through the press.

Press cake is generally captured in an open-top container or a tarpaulin. Press liquor in a 5-gallon pail or 55-gallon drum. If the press liquor goes to a pit or tank, the change in depth can be timed.

Sometimes it is possible to collect only one flow, either press cake or press liquor. In these cases, it is possible to estimate the press throughput if the solids content of the inbound material and press cake are measured.

SCREW LIFE

A screw can last anywhere from six months to twenty years. It depends on the material being pressed and how hard it is being pressed. Two good indicators of a worn screw are:

1. Decreased throughput

2. Increased moisture in the press cake

You can stop the press and clean out the discharge area and visually check for a worn screw by seeing how close the screw flights are to the screen. Be sure de-energize and lock out the press before doing so.

Premature screw failure can arise from several causes. Some are:

1. The press is allowed to run continuously with no material being fed into it

2. Very low flow is consistently fed into the press

3. Abrasive material is dewatered with high cone air pressure

Extending Screw Life:

1. Various grades of hardsurfacing rod can be used to protect the flights of a screw. For abrasive materials, Vincent will typically use a combination of colmonoy and tungsten carbide, weld applied to the face of the flights at the discharge end

2. Using a VFD in combination with a level sensor

If a worn screw is suspected, shut down and lock out the press, open the cone, and dig out the cake until the tips of the last two flights can be seen or felt. Check how badly the tips are worn. If there is 3/8″ between the tips and the screen, wear is evident. It is also an indication that the sharp edges of the flights throughout the press may have worn, becoming rounded. This can cause the flights to act like a putty knife, plastering solids against the screen, preventing water from coming through.

Worn screws are either restored locally or returned to Vincent for rebuilding. The maximum cost of a screw rebuild is around one third the cost of a new screw.

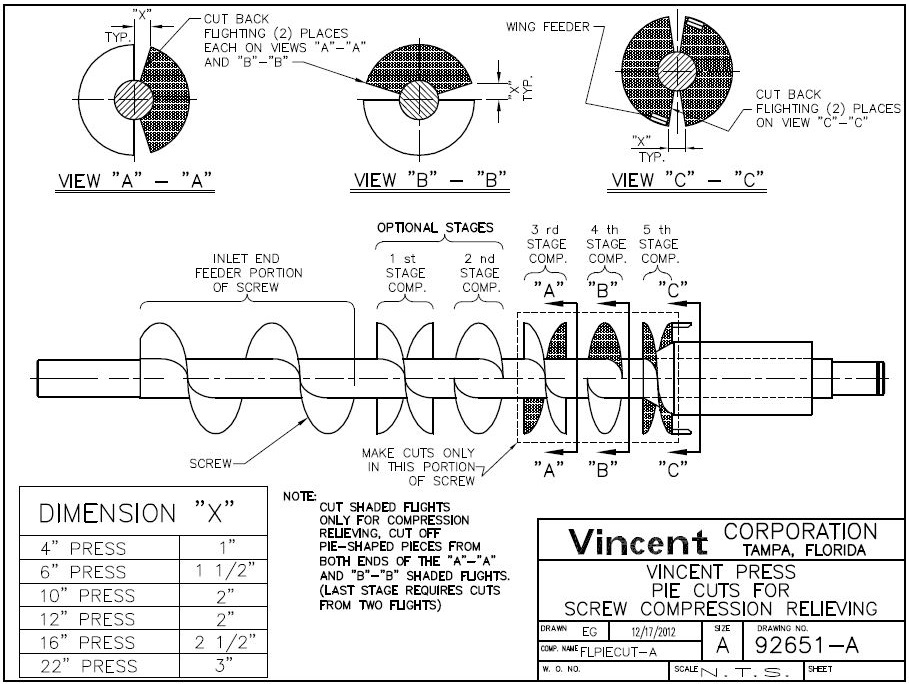

PIE CUTTING

Sometimes the compression of a screw is reduced, in the field, in an operation called “pie cutting”. This involves cutting pie-shaped segments from certain flights of the screw, leaving a butterfly (end view) configuration. The modification is done to avoid excessive compression and jamming. (The “Sterile cut” is more drastic.) Consult the factory for assistance before making this modification.

JAMMING / PLUGGING

Definitions: Vincent speaks of jamming when a press stops and the motor trips out, typically when the material inside the press is getting very, very dry. Plugging is used to describe when the press continues to run, but solids stop moving through the press.

Should a press trip out on overload because it has become jammed, a series of steps can be taken to un-jam the press. Do them in the order below, until the press is running again.

• Open the cone.

• Reverse the leads on the motor. This will cause the screw to feed material backward into the inlet hopper. Of course, if a VFD is used, this is just a matter of hitting reverse. When a press is operated in the reverse direction it is possible that solids in the press will be forced against the A-plate. This can damage the shaft seal. For this reason, run the press in reverse only for short periods of time.

• Check for tramp material in the inlet hopper.

• Try going forward again.

• Use high pressure water to clean out the discharge end of the press and thoroughly wet the material in the press by spraying the screen extensively.

If these steps don’t work, remove the screen and check for damage. Sometimes when a press is jammed, a flight on the shaft of the screw will fold backwards, toward the gearbox. This can happen if tramp metal is caught between a flight and a resistor tooth. The weld at the shaft may tear. When this happens flow through the press is greatly impeded.

Folded Flights

SCREEN BLINDING

A common problem is for the screen of the press to become blinded when solids form a mat on the inside of the screen. When this happens, the flow of press liquor coming through the screen diminishes. The level in the inlet hopper will fill up to where it overflows.

In some cases, the screen can be cleared by periodically reversing the direction of rotation of the screw. This can be programmed with many VFDs, so that the press runs forward for a given period and then reverses direction briefly for three or four revolutions of the screw when the screen starts to blind. This is one of the easiest possible solutions to test. Sometimes it is the only one that is effective.

Many other methods are used to address blinding:

1. Adding notches to the screw

2. Reducing or eliminating pressure in the inlet hopper

3. Adding press aid to the flow

4. Changing to a different screen selection

5. Reducing the screw-to-screen clearance

6. Employing a screen flush with caustic solution, acid, or high-pressure spray.

If blinding occurs after a very long period of satisfactory operation, it is usually due to wear of the screw. Rounded edges of the flights will contribute to blinding.

CHANNELING

A condition somewhat similar to purging can occur with slimy materials, like concord grapes, pineapple pulp, or spent brewers’ grain. These may tend to channel or squirt out from one side of the cone.

Some ways to try to reduce channeling:

1. Lower the air pressure on the discharge cone

2. Slow down the speed of the press

3. Add press aid to the material being dewatered

4. Reduce the inbound flow to the press

5. Install wing feeders on the end of the flights

PURGING

An undesirable condition can occur when the material being admitted to the press purges, without liquid-solid separation, from the cake discharge. This can occur especially if pressure exists in the inlet hopper.

Mechanically, purging occurs when a dry lump of press cake holds open the discharge cone. Un-pressed material will flow around this partial plug.

Purging may occur when there is a much reduced, small flow of cake coming from the press. Usually this is a sign of blinded (covered over) screens. This can be caused by a worn screw. Liquid from the inlet hopper will wick into the press cake, making it soft enough to blow out. Sometimes this condition is avoided by mounting the press inclined at about 5o above horizontal; the simplest way to do this is to place a block under the cone end of the press.

A drop in operating amps can be an indicator that a purging condition has begun. An ammeter circuit can be installed to alarm or trip the system when a reduction in motor amps occurs. This is rarely done.

The fact that the screw shaft extends beyond the cake discharge results in the formation of a donut of cake, rather than a plug. Donuts break up easier than plugs.

BRIDGING

Bridging (sometimes called rat holing) occurs in the inlet hopper when an arch or bridge forms over the screw and material doesn’t fall down. Bridging often occurs in a feed hopper attached above the press inlet hopper. Feed hoppers of this type should have at least two adjacent, vertical sides to prevent bridging.

If the bridging is occurring in the press inlet hopper, here are some possible solutions:

1. Cover the inlet hopper walls with Teflon sheets

2. Polish the inside of the inlet hopper to make it smoother

3. Install a vibrator on the inlet hopper (preferably pneumatic)

4. Add a water sluice above the inlet hopper

5. Auto-reverse the screw with the VFD

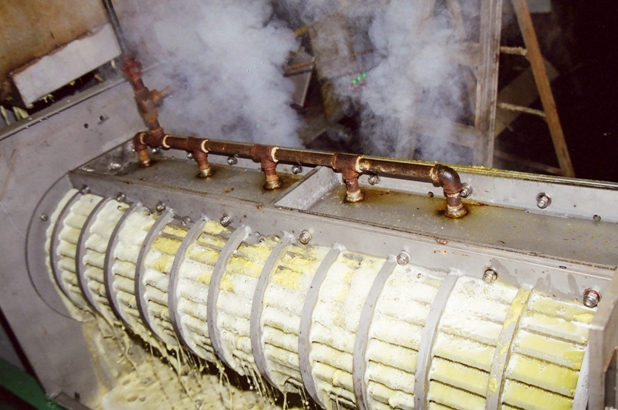

FLUID INJECTION

Resistor teeth can be drilled to permit injection of steam, solvent or water while the press is in operation. Also, these modified resistor teeth can be used for cleaning, without the need of removing the screen from the press.

Commonly alcohol injection is used to achieve in-line washing to remove sugars. Hot water injection is used to recover dissolved solids in juice production. Steam injection is used in dewatering raw organic materials.

The moisture reduction that results from steam injection is related to a chemical change that comes with blanching, or parboiling, a material. Steam injection works well on pineapple skin, citrus waste, and raw fish. Tests run with steam injection in a Vincent press at Anheuser-Busch showed little benefit. The material being pressed, spent grain, had already been “cooked” before steam was added.

Injection is achieved by drilling holes through the resistor teeth and piping these holes to a manifold outside of the screen. Photos and drawings are available from the factory. Vincent does not charge for providing a drilled resistor bar.

Steam/Liquid Injection

Commonly alcohol injection is used to achieve in-line washing to remove sugars. Hot water injection is used to recover dissolved solids in juice production. Steam injection is used in dewatering raw organic materials.

The moisture reduction that results from steam injection is related to a chemical change that comes with blanching, or parboiling, a material. Steam injection works well on pineapple skin, citrus waste, and raw fish. Tests run with steam injection in a Vincent press at Anheuser-Busch showed little benefit. The material being pressed, spent grain, had already been “cooked” before steam was added.

Injection is achieved by drilling holes through the resistor teeth and piping these holes to a manifold outside of the screen. Photos and drawings are available from the factory. Vincent does not charge for providing a drilled resistor bar.

POLYMER USAGE

In rare applications, the addition of polymer is indispensable in achieving adequate screw press performance. Polymers are added to dilute waste streams, especially to those containing very small size suspended solids. The long chain molecules of the polymer will flocculate the solids, agglomerating them to the point where they can be pressed. Under the right conditions, dramatic improvement can be achieved in press throughput, press cake moisture, and press liquor clarity.

PRESS AID

Some materials press best if a press aid is mixed into the material to be pressed. Typical press aids are rice hulls, cottonseed hulls, cellulose fiber, and ground newspaper. Ground wood is the best, but most expensive, press aid.

Press aids are most used in producing juice from deciduous fruit. The press aid gives the press something to get a bite on. Press aids also tend to hold back fines (short fibers) and prevent them from going through the screen with the press liquor. If apples are fed into a press, apple sauce will come through the screen. However, if a press aid is added to the apples, then apple juice will come through the screen.

Typically, the amount of press aid used is only 1% to 3% by weight of the flow going through the press. This will look like more than such a small percentage because press aids have a much lower bulk density than the wet materials that are being pressed, so the ratio by volume will be much higher.

HYDRATED LIME, GYPSUM, AND ALUM

Lime (calcium hydroxide) must be added to citrus peel before it can be pressed. The lime breaks down the pectin or cell walls so that the press can remove moisture. Less than 1% by weight is used. A reaction time of several minutes must be allowed prior to pressing. Lime has been used successfully in the same manner with potato, onion, tomato, and pineapple waste. It works well on acidic materials such as strawberries and coffee bean pulp. Vincent offers lime dosing equipment.

Gypsum and alum salts are also effective chemical press aids. They are typically used in dewatering sugar beet pulp, and they have rarely been found effective on other materials.

CLEANING

Commonly, material is cleared from a press by stopping the inbound flow, setting the discharge cone in the withdrawn position, and running the press for a few minutes until no further material is discharged. This will leave some material inside the press, which can be handy for forming a plug at the cake discharge when the press is restarted.

Material will leave a press only if there is additional inbound material forcing it out. This makes it difficult to completely clear material from inside a press without removing the screen. One technique used successfully is to feed crushed ice into the press. Water must be fed along with the ice to prevent jamming. When the ice melts, the press will be relatively clean inside.

There are applications in which the press must be cleaned frequently, such as once a shift, in order to meet sanitary regulations. In these cases, the screen can be removed from the press in order to remove residual material. A spare screen assembly may be kept, submerged in cleaning solution, in order to minimize the downtime required.

Once the screen is removed, the screw and screen are scrubbed with caustic solution.

In one case with a KP-16 press, the liquid discharge drain is blocked shut so that caustic solution can be allowed to fill the collection pan. This cleaning is performed without removing the screen from the press.

Cleaning the inside of the screen can be achieved, at least to some extent, by injecting water through the resistor teeth. Holes must be drilled in the resistor teeth to make this p

It is unusual that the outside of the screen ever needs to be cleaned. Spray systems for this can be built into the press at the Vincent factory. Alternatively, a pressure washer or swabbing with acid solution can be used.

MAINTENANCE

CHECKING SCREW-TO-SCREEN CLEARANCE

Generally, the clearance between the screw and the screen is 1/32″, plus or minus 1/32″. The screw should not rub the screen hard, as it can cause wear and premature failure of the screen. Tighter clearance is used with materials that blind the screen, such as onion skins. Greater clearance, 1/16″, is used with eggshells, pectin, xanthan gum, and corn husk. With a clearance greater than 3/16″, the dewatering performance of the press can start to deteriorate; this depends a lot on the type of material being dewatered.

The easiest way to check for screw wear is to open the cone, clean out the material and measure the distance between the screw flight and the inside of the screen. For precise measurements:

• Wedgewire screens – a feeler gauge can be slipped through and along a slot until it hits the edge of the screw. Measure from the outside of the screen in to the edge of the flight; then subtract the thickness of the wedgewire (generally either 0.250″ or 0.375″) from the measured depth in order to calculate the clearance.

• Perforated screen installations – a depth gauge can be used to measure the screw-to-screen clearance. This is done by first finding an area where the screw flight is next to the screen; poking a straightened paper clip through the screen is handy for this purpose. The depth from the outside of the screen to the edge of the flight is measured, and then the thickness of the screen is subtracted from that measurement. [3/32″ perf is 0.075″ thick; 0.050″ perf is 0.048 thick; 1/32″ perf is 0.024″ thick; 0.023″ perf is 0.015″ thick; 3/8″ perf back up screen is 0.120″ thick.]

If a screw rubs against the screen in a given area, it may be best to grind some off the OD of the screw. Prussian Blue can be useful in finding the spot that is rubbing.

Wedgewire Depth Gage (L) and Perforated Depth Gage (R)

SCREEN REMOVAL AND REPLACEMENT

Wedgewire screens in Vincent presses can be reversed in order to achieve double life. That is, wear starts at the cake discharge end of the press. When this occurs, the screen can be turned 180o so that the fresh inlet section is then in the discharge area.

In the case of screen failure, frequently a solid patch can be welded onto the screen, from the outside. This is simple as the screen need not be removed from the press.

Wedgewire screens may become smeared from being wiped by the screw or by hard press cake. Wedgewire screens generally work satisfactorily with 30% or even more of their surface smeared over. Usually press liquor will not come through a smeared area of a wedgewire screen. If it becomes an issue, it is corrected by running a box cutter blade through the slots.

Screens for the KP-24 and KP-30 are in two halves, a left and a right. These can be removed from the sides of the press after the bolts holding them to the top and bottom resistor bars have been removed. There are likely bolts through the end flanges of the screens into the B- and C-plates as well.

Replacement thin gage screens are provided with 1/4″ extra length. This allows 1/8″ at either end to be peened over. The resulting 1/8″ flange both helps hold the screen in place and prevents the screen from being snagged by the screw.

Excessive rubbing between a screw and the screen can be corrected by grinding the interference off the edge of the screw. Prussian Blue, applied to either the screw or the screen, can be useful.

SCREW REMOVAL AND REPLACEMENT

The screw is removed through the hole in the C- and D-plates, at the cake discharge end of the press. The operation can be difficult the first time, so we recommend consulting with the factory before getting started.

First of all, remove the four bolts holding the shaft seal housing to the A Plate. This will prevent damage when the screw is decoupled from the gearbox.

Next, remove the screen of the press, following the instructions in the Screen Removal section above.

At the discharge end, disconnect air lines to from air cylinders. If autolubes are present, disconnect as needed. Remove the cylinder rod to cone connection, then remove the split collar on the end of the screw. Next, back off the set screws holding the bearing. Support the screw in the screen area near the C-plate. Remove the center plate (also known as the thrust plate/flange) on the D-plate and remove the entire assembly with air cylinders and bearings attached. If the weight is excessive, you may want to remove each component.

At the inlet end of the press, remove the cover over the coupling. Disconnect the coupling and remove.

Pull the screw from the end of the press, supporting and moving the support as you remove the screw.

There are two ways to avoid excessive rubbing between a new screw and the screen: Either shims can be placed between the screen flanges and the resistor bars, or the interference can be ground off the edge of the screw. To eliminate the high spots, coat the edge of the screw with Prussian Blue, tighten the assembly, turn the screw, remove the screen, and then grind the screw where interference has occurred.

LUBRICATION

Lubrication is something we generally review with customer personnel during start-up. It is pretty straight forward:

CONE BUSHINGS: Once a shift or more often

DISCHARGE BEARING: Monthly

SHAFT SEAL: Monthly

GEARBOX: Annually

MOTOR: Never

The most critical lubrication item has to do with the cone bushings. Before starting up a new press, the cone should be run in and out a few times to spread the grease around.

Lubrication of the cone bushings depends a lot on what is being pressed. With orange peel, there is enough press liquor juice acting as a lubricant that the bushings are lubricated only at the end of the processing season (to keep it from locking up on dried-out peel juice). The other extreme is at a paper mill where boiler fuel is made out of reject fiber. There is no free water left in the press cake, so everything is very hot and dry. We often supply a 900 psi ATS autolube on paper mill jobs. Another tough application is with vapor tight presses where there is apt to be solvent getting into the cone bushings. The solvent can dissolve and wash out the grease, so we like to see frequent lubrication of the cone bushings. (Food grade grease is used in this application since food ingredients are being produced by the press.)

In any case, we tell the operators to run the cone open and closed at least once a shift because this will spread the grease around. This is done with the press in operation.

The bearing holding the screw gets greased once per week. Whatever grease the customer normally uses will be fine.

The shaft seal housing may have a grease fitting. This grease is to prevent fiber from getting into the seal. The seal should be given a shot of grease at least monthly.

The gearbox oil should be changed once a year. Use mineral oil for a normal 1800/1500 RPM input. Use the same grade oil, but synthetic, for input speeds of 2,400 RPM or more.

Some Nord gearboxes have an autolube canister located in a motor adapter portion of the gearbox. It is located under a cast iron cap. This autolube should be actuated when the press is placed in service. Nord recommends replacing this autolube once a year.

The air regulator used with the discharge cone air cylinder may have a lubricant jar. If so, Vincent includes a can of light oil along with the air regulator which comes with our screw presses. The jar should be filled when placing the press in service and when the jar is empty, about once a year. It takes very light (sewing machine) oil. The oil helps prevent corrosion inside the air cylinder. (Most air cylinder manufacturers no longer recommend the use of lubricators, so we no longer supply them.)

Click the link below for a pdf version of this page.