As far back as the 1960’s Vincent screw presses were used for squeezing juice out of alfalfa. Surprisingly, alfalfa is mentioned in at least twenty issues of Pressing News on our web site. PN#46, from 1996, details many of these applications. It seems that every four years or so we sell an alfalfa press, almost always for nutraceutical or cosmetics production.

More frequently, we rent small presses for trials and pilot runs. Last year our rental equipment was used in two separate projects sponsored by the Danish government. For these we shipped a container load of screw presses and shredders to RUNI, our European agent, who coordinated the activities.

One project, run with Aarhus University on their Foulum campus, used a single screw CP-10 press. The other project was conducted with a twin screw TSP-12 screw press by staff from both Aalborg and Aarhus universities. These trials were conducted at Nybro, the last alfalfa drying facility left in Denmark.

The work in Denmark was done mostly with red clover and some rye grass. More recently we have run trials with winter wheat grass in Kansas. All of these grasses have the same pressing characteristics as alfalfa. The Danish work focused on organic protein recovery for human consumption. Press liquor was screened and then dried into powder. The residual fiber was used for feeding dairy cows.

These trials definitely advanced our knowledge and understanding of processing grasses. Being able to compare single screw to twin screw presses proved invaluable.

We had known all along that a severe capacity reduction factor (75% to 80%) had to be applied when pressing alfalfa. We had attributed this to the low bulk density of as-harvested alfalfa. In reality, the capacity problem is equally attributed to the tendency for these grasses to slip inside the press.

The positive displacement characteristic of the twin screw press resulted greatly improved throughput. Good performance (50% juice yield) was achieved with throughput of half of the nominal “brochure” rating. Going from an 80% to only 50% capacity de-rating is a major technical advance.

It was also determined that very high screw speeds — triple the normal rpm — were required to overcome the slippage and bulk density problems. In order to sustain torque at these high speeds, larger than normal motors were required.

Using conical screw shaft configurations improved performance. Both perforated and wedgewire screens did well.

We were also able to test Vincent shredders on the harvested alfalfa. They jammed and were removed from service. A flail chopper type of shredder would probably work, as would the old Olson macerator design.

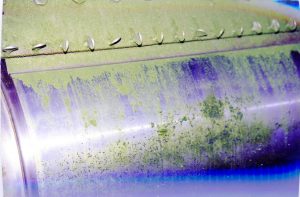

TWIN SCREW TSP-12 SCREENING PRESS LIQUOR

PRESS LIQUOR FROM DECANTER PRESS LIQUOR DRYER