April 13, 2020

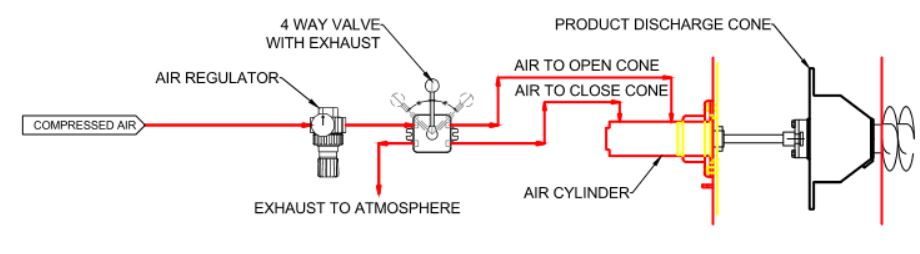

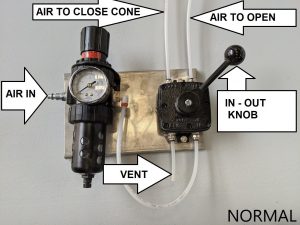

For over fifty years Vincent has normally piped the air pressure regulators for our screw presses this way:

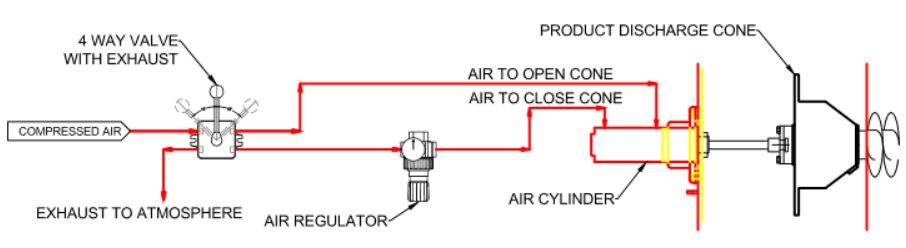

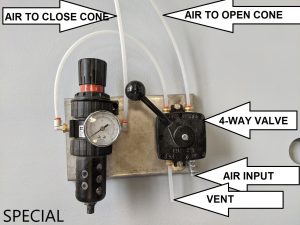

But there are special situations where you may want to pipe this way:

Let’s start with why the air pressure regulator is needed in the first place. Force exerted by the discharge cone at the cake discharge results in compressing the material going through the screw press. The force comes from one or more air cylinders pushing the cone. When the cone is pushed shut, the screw must overcome the force in order to push press cake out of the press. Obviously, the more pressure pushing this cone shut, the more the screw must squeeze the material to get it past the cone. Setting the air pressure with a regulator allows adjusting the press for optimal performance.

At times this same air pressure is used to pull open the discharge cone. It is done for things like inspection, cleaning, maintenance, and relief from a jammed condition. A manual 4-way valve is used to switch from “closed” to “open”. All Vincent presses are supplied with an air pressure regulator along with a Parker 4-way reversing valve.

Here is the tricky part. You can see that with the normal plumbing, the air pressure used to either open or close the cone is the same, as set with the regulator. Usually this is okay. But there are times when it would be advantageous to open the cone faster, or with more force, using full plant air pressure. The new special piping arrangement allows this to happen.

Special situations where high air pressure is advantageous for opening the cone would be when using a Red Lion amps sensor or the Vincent Cone Timer. The Red Lion instrument monitors press motor amps. When the amps go high, the cone is opened by switching the 4-way valve. The Cone Timer is similar. Rather than sensing amps, it has a simple timer which opens the cone for a few seconds every time a fixed pre-set period elapses.

We need to note that the new piping arrangement works only with the Series VP, CP, TSP, and VDC presses. These have the cone actuator mechanism configured to pull the cone open when the air is reversed. However, our most popular presses, the Series KP, are usually arranged so that the actuator arm opens freely without pulling on the cone. (There are a number of minor exceptions to this.)

Also, here is how a 4-way air valve works: Moving the 4-way valve handle from one position to the other causes the air cylinder to push in the opposite direction. To achieve this, the 4-way valve must relieve air pressure from the side of the cylinder which was previously pressurized, while simultaneously opening air to the other side of the cylinder. There is a vent line (exhaust) on the 4-way valve which allows air to escape when pressure is switched from one end of the air cylinder to the other. Thus there is a burst of air through the vent line whenever the valve handle is moved from one position to the other.

ISSUE #323