November 3, 2022

Over the past four years Vincent Corporation has worked closely with an industrial engineering and design partner investing significantly in custom built equipment for screw press applications. Our bulk handling feed, mixing/blending, filtration, solvent recovery, distillation and automation systems benefit from decades of experience working with hundreds of customers across diverse industries.

Bulk handling systems begin with a live bottom surge bin mounted on load cells to control feed rate, facilitating 1-6 hours of continuous screw press operation. Current builds are for 110, 450, 700 and 3000 lb/hr operation with different designs available for a wide range of material. These designs provide the ability, when required, to gently convey material as well apply maceration, milling and mixing of material during transport.

Our horizontal reaction conveyor adds mixing/blending functionality to our bulk handling feed system and has proven to be one of our hottest sellers. This unit is equipped with a multiple port spray manifold and independent pressure controls for dosing and wash/rinse applications. The build is compatible with caustic solution as well as a wide range of volatile solvents. We have delivered multiple jacketed models for steam heated or cold temp (-30c) operation. Staged compression and expansion functionality aids in diffusion to reduce residence time requirements. Units up to 30” screw and 40’ troughs are available. Counter-current extraction configurations for high residence time applications are available. Additional process controls allow for a range of agitation, from 90% forward 10% fallback to 60% forward 40% fallback operation. Companion flanges are designed to mate up with any size Vincent screw press, providing a direct feed closed loop processing solution.

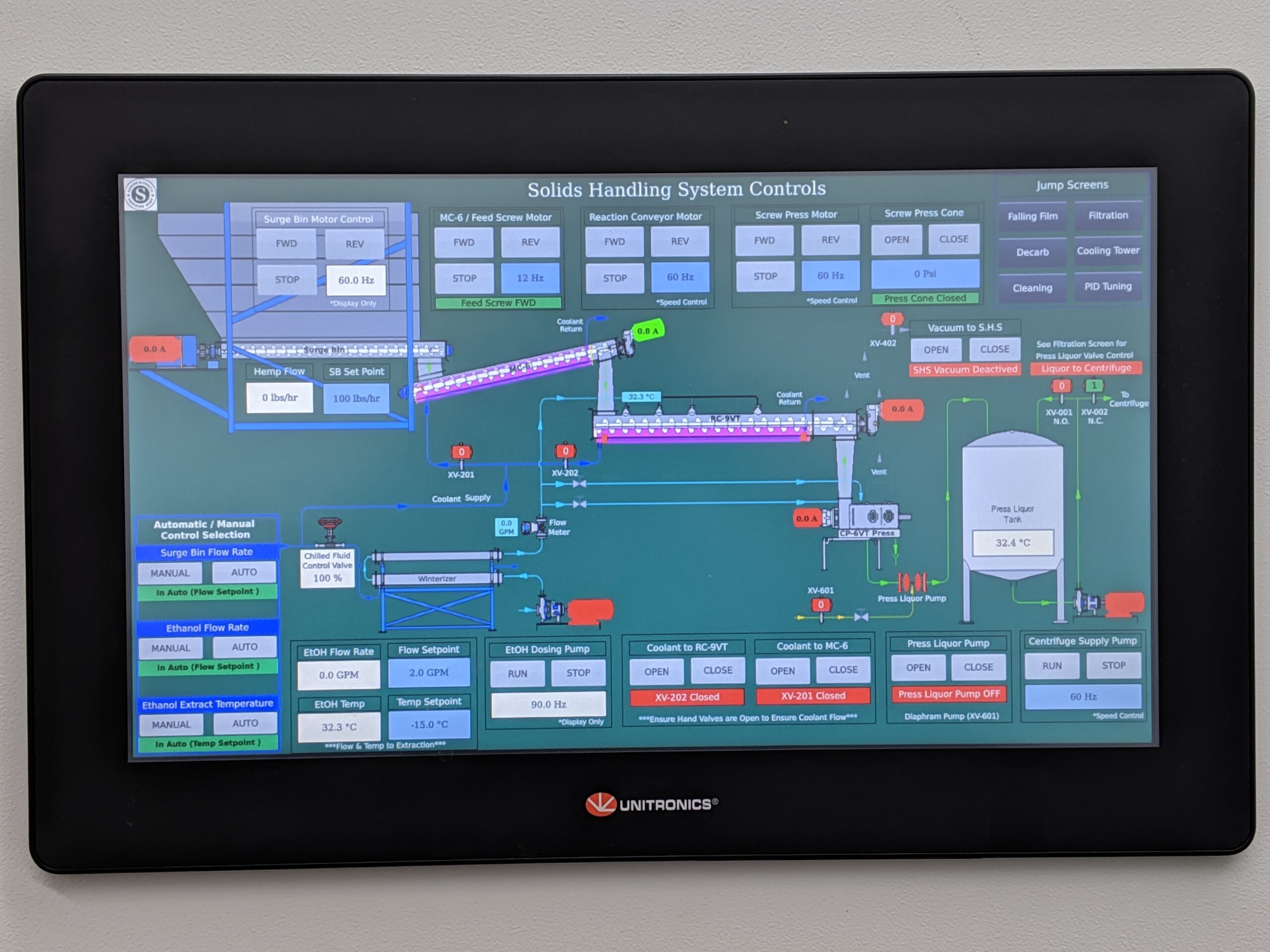

System automation is an essential component of any high volume closed loop processing facility. Our control panels are built and programmed in-house, incorporating programmable logic controls for fail safes, start-up routines as well as shut-down and CIP requirements. Our HMI screens give operators process flow visibility as well as complete control of equipment via a supplied control panel, webservices to smart phones as well as tablet devices. Our engineers have significant experience with Allen Bradley, Siemens and Unitronics platforms. We provide a complete copy of source code at hand-over, giving customers the flexibility to maintain their own systems. Additional space and channels are provided with every panel for future process control requirements.

ISSUE #345