July 20, 2020

When it comes to maintenance issues, our most common phone call has to do with removing a screw shaft from a Nord hollow bore gearbox. Vincent uses these Nord gearboxes in the Series KP and CP screw presses.

With these, the gearbox is flange-mounted to the side of the inlet hopper (called the “A-Plate”). That means that end of the screw is inside the gearbox.

First of all, don’t forget to remove the big bolt at the end of the screw, located under the motor. It holds the screw in the gearbox. You will not be the first to overlook that detail. (When you reinstall the screw, be sure to use Loctite on the threads of that bolt.) Also, loosen the four bolts holding the seal housing so that it will not be damaged when the screw drops out of the gearbox.

The screw is removed from the cake discharge end of the press. That means that the first step is to remove the tailstock assembly with the air cylinder(s), outboard support bushing/bearing, and the cone actuator mechanism. Next to be removed are the discharge cone, the screen, and the resistor bar(s). Finally it is now just a matter of pulling or pushing the screw out of the gearbox.

The pusher tool must be perfectly straight with the screw before it can be pushed out. Since the outboard support bushing or bearing will have been removed, you may have to lift up the end of the screw a bit for it to be straight with the tool. Alternatively, the tailstock of the KP-6 through KP-16 can be temporarily reinstalled to support and properly align the screw.

Generally it is possible to pry the flights of the screw at the B- or A-plate, and the screw will come out.

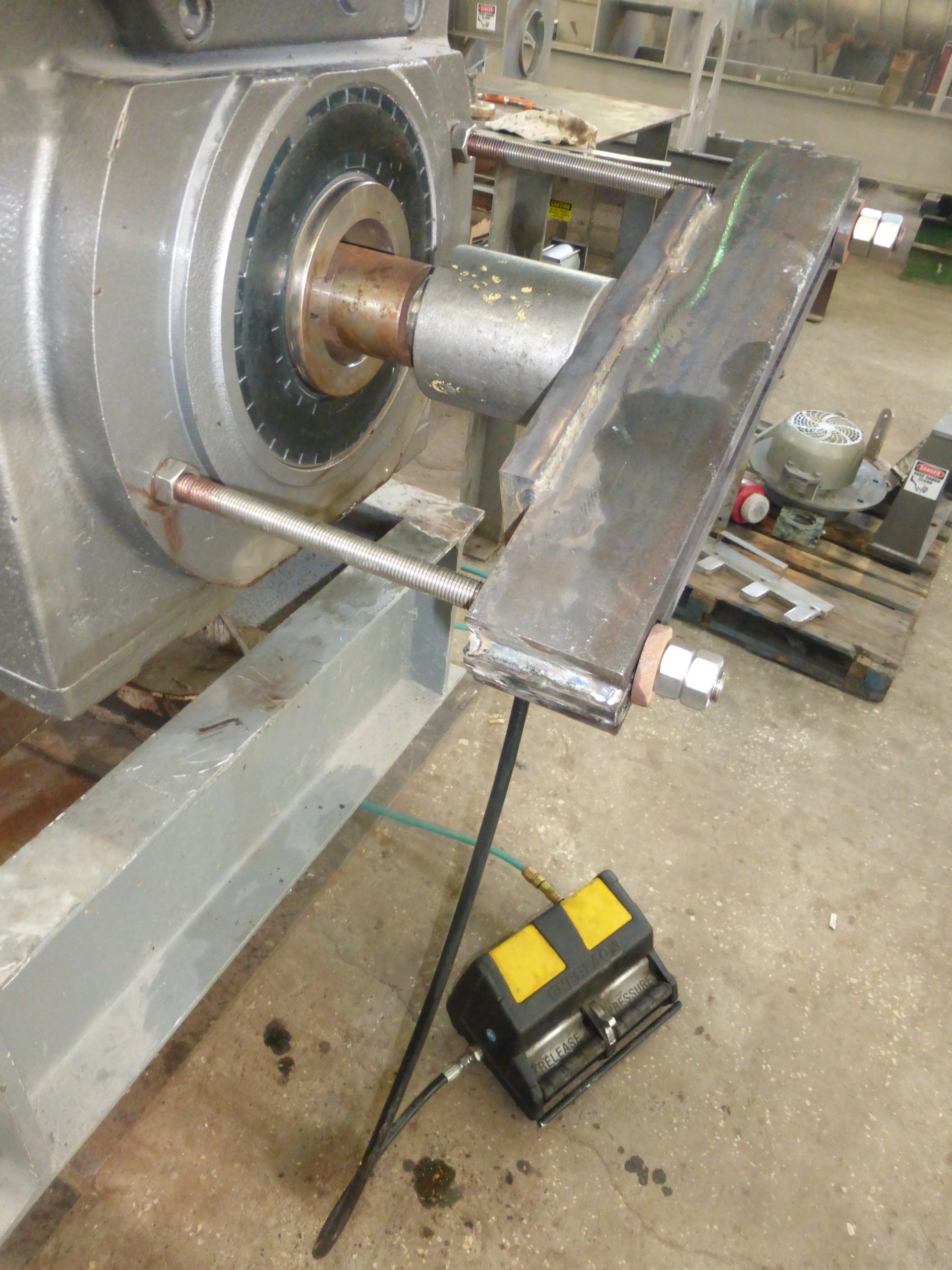

For some of the larger hollow bore gearboxes Vincent can supply a threaded pushing tool. As seen in the photo, a strong-back holds two rods which screw into the gearbox, straddling the end of the screw. A threaded rod with fine thread and lots of Anti-Seize is used to force the screw out of the box. (Note that the anchor holes in the gearbox will have metric threads; we can walk you through that problem.)

Alternatively, some maintenance departments use a hydraulic porta power to push the screw out of the gearbox. Note that the hydraulic cylinder must be held in very good alignment with the axis of the screw shaft.

If the screw still does not come out, then it gets bad: You will have to cut the screw in half between the outlet of the gearbox and the seal housing on the A-plate.

To salvage the gearbox, remove it and use a hydraulic press to push the stub of the screw out of the gearbox. It is beneficial to tip the gearbox and spray PB Blaster or a similar solvent/lubricant into the bore. If allowed to sit overnight, sometimes the solvent will seep in and free the shaft.

In really severe cases, where the key may have rolled in the gearbox, the gearbox can be put in a vertical boring mill, and the stub shaft of the screw can be bored out of the gearbox. After boring a hole the stub, we fill it with dry ice. The shrinkage that results greatly facilitates removing the sleeve left in the gearbox.

If the screw has been sawed or burned it in half, it can be returned to Vincent for repair. We need the long portion, the one with the flights. You can keep the stub.

Having said all that, it may be possible to repair the screw without taking it out of the gearbox. Flights which are not too severely bent can be bent back into position by gripping the flight with an adjustable wrench. Be sure to wear heavy leather gloves when doing this, because the wrench will have a strong tendency to slip loose. See the photo below.

If you are straightening the flights with hammer blows, applying heat with an oxyacetylene torch can help.

If the end of a flight has been ripped off the shaft, breaking loose the weld, or if it is severely bent, just use an angle grinder to cut away the bad part. Similarly, bent resistor teeth can also be trimmed with a grinder so that they do not hit the flights. That will get you going again.

When it comes to re-installing a screw in a gearbox, be sure to put Anti-Seize or Bostik Never-Seez on the end of the shaft. At the factory we also wrap Teflon tape at the step in the screw shaft which seats against the outboard thrust bearing of the gearbox. Maybe the screw will come out easier next time.